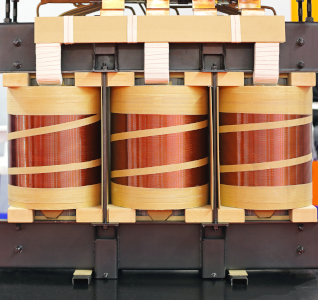

Our team at Electric Power Systems has extensive experience in the electrical industry, and we understand the important role transformers play in the electrical grid. These devices alter the voltage of electrical current as it travels through the grid, ensuring the current is the right strength for the circuits in the buildings that draw power from the larger electrical system. While transformers are designed to last a long time, they do require occasional maintenance and repairs, such as transformer coil rewind services. In this article, our team will explain how the transformer coil rewind process works.

Our team at Electric Power Systems has extensive experience in the electrical industry, and we understand the important role transformers play in the electrical grid. These devices alter the voltage of electrical current as it travels through the grid, ensuring the current is the right strength for the circuits in the buildings that draw power from the larger electrical system. While transformers are designed to last a long time, they do require occasional maintenance and repairs, such as transformer coil rewind services. In this article, our team will explain how the transformer coil rewind process works.

- Calculate Size – The first step in the transformer coil rewind process is calculating the power requirements. To do this, we multiply the required voltage by the required current (or amperage). This tells us what size the core of the transformer needs to be.

- Disassembly – Once we’ve made the necessary calculations, we will disconnect the transformer from the grid and take it apart. We’ll remove all screws and other connecting pieces and remove the laminated layers from around the iron core.

- Unwinding – The next step in transformer coil rewinding is to unwind the coils. As we do this, we’ll count the number of turns the wire makes. We’ll then use this information to calculate how many turns we will need to create as we wind new coils to achieve the required voltage and current.

- Rewinding and Reassembly – The next step is to wind new coils around the core, using our calculations from before to determine how many loops to make. Once this step is complete, we’ll reassemble the transformer and hook it back up to the grid.